Cutting round vs. flat metal pieces is a fundamental topic for many industries, especially those in manufacturing and engineering. The choice between cutting round and flat metal pieces plays a critical role in determining the efficiency and quality of production processes. Understanding the differences and nuances can greatly enhance a team’s capabilities and the quality of the final product.

In this article, we’ll delve into the specifics of each method, exploring their applications, advantages, and potential pitfalls. Whether you’re planning to cut round or flat pieces, knowing their respective strengths and weaknesses will help you make the most informed decisions.

What Influences the Choice?

There are several factors to consider when choosing between cutting round vs. flat metal pieces. These include the type of metal being used, the required level of precision, and the intended application of the metal parts. Each factor can affect the overall outcome of the cutting process, influencing the quality, efficiency, and cost involved.

Material Considerations

The type of material is a fundamental consideration. Metal materials such as steel, aluminum, and copper have different characteristics that can influence how they are cut. For example, cutting aluminum might require specific techniques for high accuracy, as detailed here.

Precision and Accuracy Needs

When it comes to precision, round pieces often require different cutting techniques compared to flat pieces. As noted in our overview on precision metal cutting, the precision needs can significantly impact the choice of cutting tools and methods. Understanding the distinction helps manufacturers decide on the appropriate cutting technology to use.

Comparing Round and Flat Metal Cutting

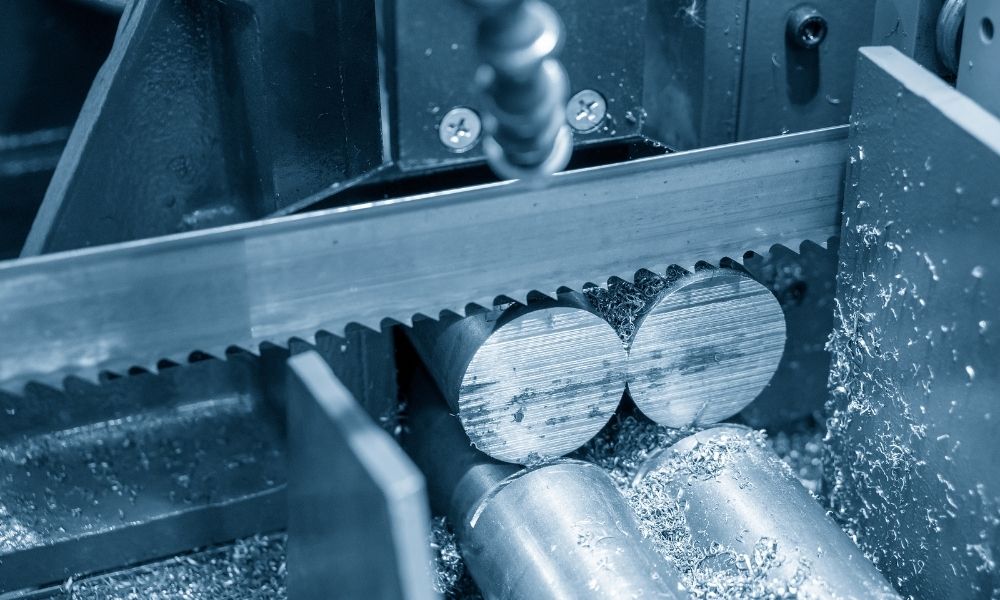

Round Metal Cutting Techniques

Round metalwork often entails techniques like turning, facing, and slicing. The aim is to achieve smooth, precise surfaces around a cylindrical shape that might be used in rotating machinery parts.

Flat Metal Cutting Techniques

Flat metal, on the other hand, often utilizes techniques such as laser cutting and waterjet cutting. For instance, waterjet cutting is extensively detailed in this guide, offering precision and minimal waste production for flat surfaces.

Tools Utilized

The tools for cutting these different types often vary due to the nature of the material’s shape and required accuracy. While round metals might need lathes, flat metals commonly require band saws or advanced tools like laser and waterjet systems.

Practical Applications

The industry application plays a significant role in determining whether to use round or flat metal pieces. Round pieces are often used in gears, bearings, and shafts, while flat pieces are common in sheet metal projects and structural supports. The choice of cutting influences how well each piece will perform in its respective application.

Safety Concerns and Best Practices

Adhering to safety practices is crucial when handling any cutting equipment. For detailed safety protocols, you can refer to these tips, ensuring safety remains a top priority during the cutting process. Proper equipment and protective gear are necessary to prevent accidents and maintain a safe work environment.

Advanced Technologies in Metal Cutting

We’ve seen an evolution in metal cutting technologies. Today, Computer-Assisted Design (CAD) plays a pivotal role in enhancing cutting precision and reducing errors. For in-depth insights, check out CAD design techniques in this article.

Case Study Example

Consider a scenario where manufacturers opt for flat metal cutting techniques for intricate automotive parts. In such cases, laser cutting might be the best approach due to its precision and efficiency in mass production settings, as suggested by leading experts in the field.

Conclusion

Choosing between cutting round vs. flat metal pieces requires understanding their differences, advantages, applications, and potential limitations. By considering factors such as material type, precision needs, and industry applications, manufacturers can choose the best methods tailored to their specific requirements.

FAQ Section

1. What is the main difference between cutting round and flat metal?

Round metal cutting often requires techniques that cater to cylindrical shapes, while flat metal cutting is more suited for surfaces requiring precision and accuracy, like those achieved with laser cuttings.

2. Which cutting method is more cost-effective?

It depends on the application. For large production volumes with high precision needs, technologies like laser and waterjet are usually more cost-effective due to their efficiency and speed.

3. How does safety differ between the two cutting methods?

Both methods require strict adherence to safety protocols. However, methods involving advanced machinery such as lasers may necessitate additional safety measures due to their increased complexity.

This article contains affiliate links. We may earn a commission at no extra cost to you.