In the ever-evolving world of industrial manufacturing, the process of cutting metal foils stands as a critical component of precision engineering. This vital operation is not only about dividing metal into specific shapes but also involves understanding the techniques that lead to minimal waste and high efficiency. With various industries relying on accurately cut metal for their products, mastering this craft is paramount. Here, we explore the state-of-the-art practices and innovations that have reshaped the landscape of metal foil cutting in 2024.

When it comes to cutting metal foils, there are several strategies and tools that manufacturers need to be familiar with. This process is crucial for creating components used in electronics, automotive, and aerospace industries, among others. As technology advances, so do the methods for achieving the desired precision and quality.

Understanding Metal Foil Types

Before diving into the techniques, it’s important to understand the types of metal foils available. Common types include aluminum, copper, titanium, and stainless steel. Each material offers unique properties that influence how they can be cut effectively.

Aluminum Foil

Known for its lightweight nature and resistance to oxidation, aluminum is often used in applications that require thermal and electrical conductivity.

Copper Foil

Copper is prized for its superior electrical conductivity, making it ideal for electrical components and shielded electronics.

Titanium and Stainless Steel Foils

These materials are known for their strength and durability, suitable for demanding environments where corrosion resistance is essential.

Precision Cutting Methods

To achieve the best results in cutting metal foils, manufacturers use several precision cutting methods:

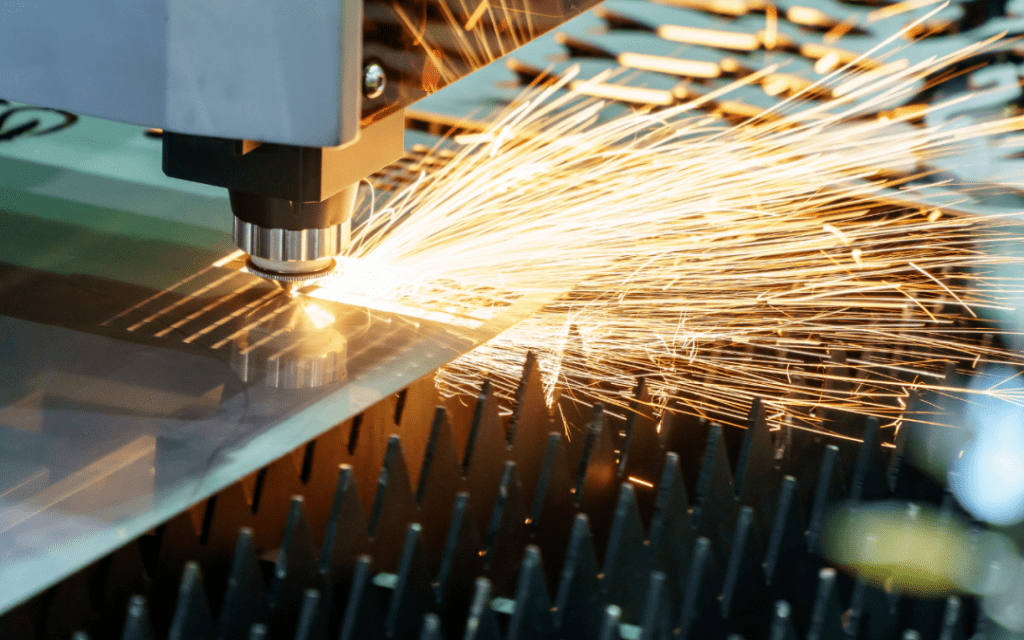

Laser Cutting

This method involves using a concentrated laser beam to slice through metals. Laser cutting offers high precision and can be controlled digitally, allowing for intricate designs and patterns.

Water Jet Cutting

Water jet cutting uses a high-pressure stream of water, often mixed with abrasive materials, to cut through metal. This technique is beneficial for metals that are heat-sensitive, as it doesnt generate heat.

Mechanical Cutting

Traditional methods such as shearing, punching, and sawing are still widely used for their efficiency and cost-effectiveness in certain situations.

The Role of Automation in Metal Foil Cutting

The integration of automation has revolutionized metal foil cutting by increasing precision and reducing human error. Automated presses and robotic arms can perform repetitive tasks with consistent accuracy. This not only speeds up production but also ensures uniform quality.

Cad Integration

Computer-aided design (CAD) systems enable manufacturers to design precision cuts digitally before they’re executed in reality. This process enhances accuracy and allows for easy adjustments.

Environmental Considerations

The push for sustainability has encouraged the development of techniques that minimize waste during the metal foil cutting process. Recyclable materials and energy-efficient machines are becoming industry standards.

For more tips on minimizing material waste and achieving precision, check this guide.

Safety Measures in Metal Foil Cutting

Safety is an essential aspect of cutting metal foils. Proper training and equipment maintenance are crucial for preventing accidents. Facilities should adhere to safety regulations and ensure that all workers are equipped with protective gear.

Explore more about safety precautions at safety tips.

Innovations and Future Trends

The future of cutting metal foils looks promising with innovations such as smart materials and AI-assisted cutting processes. These advancements are expected to enhance efficiency and open new possibilities in manufacturing.

Smart Materials

Materials that can change properties under external stimuli offer potential in creating adaptive and highly optimized manufacturing processes.

AI-assisted Processes

Artificial intelligence can analyze patterns and optimize cutting routes to maximize material usage while reducing time and costs.

For a deeper understanding of these advanced techniques, check the precision cutting overview.

FAQ

- What are the common methods for cutting metal foils? The most common methods include laser cutting, water jet cutting, and mechanical cutting.

- How has automation impacted metal foil cutting? Automation has greatly increased precision and efficiency, allowing for consistent quality and reduced error.

- Why is aluminum a preferred material for metal foils? Aluminum is lightweight, resistant to oxidation, and offers excellent thermal and electrical conductivity, making it a versatile material.

This article contains affiliate links. We may earn a commission at no extra cost to you.