When it comes to cutting carbon steel precisely, its crucial for professionals in various industries to employ the most reliable techniques. Many might wonder how exactly this is achieved, especially in todays constantly evolving technological landscape. This article explores the methods and technological innovations in the realm of precision cutting of carbon steel, providing insights into how industry leaders maintain exceptional standards.

The Importance of Precision in Steel Cutting

Precision is everything in the world of manufacturing. Especially when it involves carbon steel, a material known for its durability and strength, achieving accurate cuts is vital. Not only does precision ensure minimal waste, but it also plays a significant role in the function and quality of the final product. For detailed guidance on precision metal cutting, check this in-depth guide.

Why Carbon Steel Requires Special Techniques

Carbon steels composition poses unique challenges for cutting. The materials hardness and various grades demand specific tools and techniques to ensure effective slicing. Given these challenges, utilizing customized approaches allows for overcoming these hurdles while retaining the steels integrity.

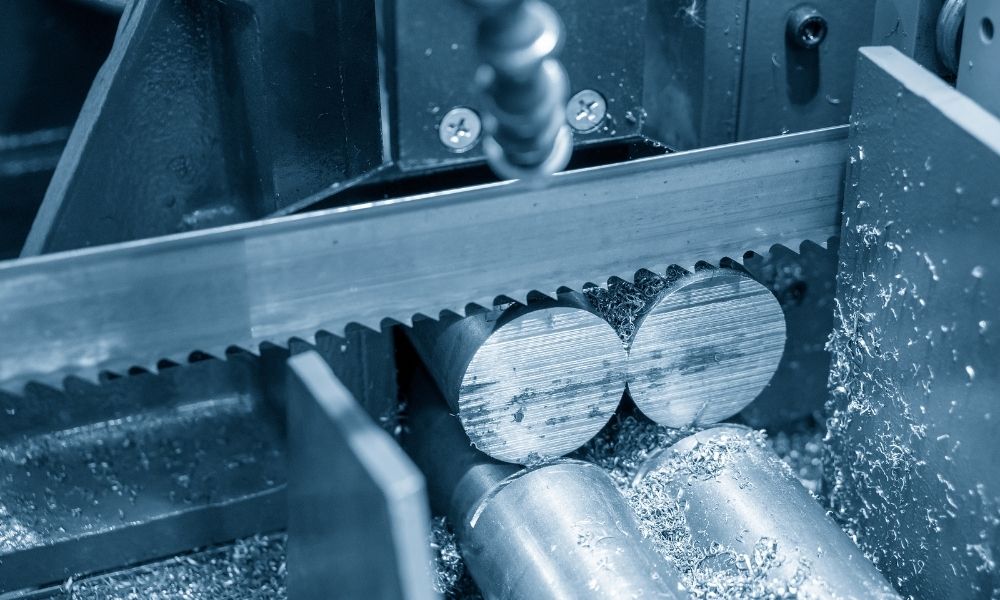

Advanced Tools and Their Role in Precision

The industry uses various cutting-edge tools that enable precision when working with carbon steel. The following segments explore these tools, highlighting their effectiveness and role in achieving immaculate results.

Laser Cutting: The Precision Powerhouse

Laser cutting stands out as one of the most precise methods available. Utilizing a highly focused laser beam, it melts or vaporizes the areas targeted without affecting the whole surface. For manufacturers focusing on fine detailing, laser cutting becomes an invaluable tool.

Plasma Cutting: Versatility Meets Precision

Plasma cutting introduces its own unique benefits by employing an electric arc to cut through carbon steel. This method efficiently handles thicker sheets and provides both speed and detail, suitable for diverse applications in the industry.

Challenges in Precision Cutting of Carbon Steel

Despite advances, precision cutting faces various challenges, such as material thickness variations and thermal distortions. Addressing these issues requires continuous monitoring and leveraging the latest technological tools.

Material Thickness and Consistency Challenges

Inconsistent material thickness can lead to inaccurate cuts or wasted resources. Ensuring the materials uniformity before cutting is a proactive measure against such errors. Visit safety tips to prevent common mishaps.

Heat Affected Zones

This is a byproduct of high-temperature procedures like laser and plasma cutting. Understanding the extent of these zones and managing them is essential in preserving the element’s structural integrity.

Innovations Driving Precision in Carbon Steel Cutting

Innovations play a pivotal role in overcoming traditional challenges associated with precision cutting. Here, we examine how industry leaders and innovators are creating new benchmarks.

Computer-Aided Design (CAD) Systems

CAD systems offer precision-cutting operators the chance to visualize the intended cuts. Read more on how CAD systems revolutionize cutting.

Ultrasonic Metal Cutting Technology

Characterized by its ability to cut without generating significant heat, ultrasonic technology presents a groundbreaking method for precision. For those vexed by traditional heat-related techniques, this alternative can be an excellent option.

Conclusion

In summary, cutting carbon steel precisely is a fundamental process that involves understanding materials, selecting the right tools, and leveraging modern innovations. As industries continue to grow and evolve, these cutting methods are becoming increasingly streamlined, benefiting both productivity and quality.

FAQs

What are the best methods for cutting carbon steel?

The most effective methods include laser cutting, plasma cutting, and thermal cutting techniques, with each presenting unique advantages based on the task.

How does computer-aided design impact precision?

CAD allows for meticulous planning, reducing error risks and enhancing the accuracy of the cuts.

Why is laser cutting preferable for thin materials?

Laser cutting provides unparalleled precision, making it ideal for intricate detailing on thinner materials.

This article contains affiliate links. We may earn a commission at no extra cost to you.