Understanding the differences between compound die vs progressive die stamping is crucial for industrial manufacturers and those involved in metalworking. These two stamping techniques are fundamental to the production of high-quality metal parts and components. By examining their unique characteristics, users can make informed decisions in choosing the right method for their specific applications.

Both the compound die and the progressive die approaches offer distinct advantages and are applied based on the complexity and requirements of the metal stamping process. Let’s dive deeper into exploring what distinguishes these methods and how they cater to different manufacturing needs.

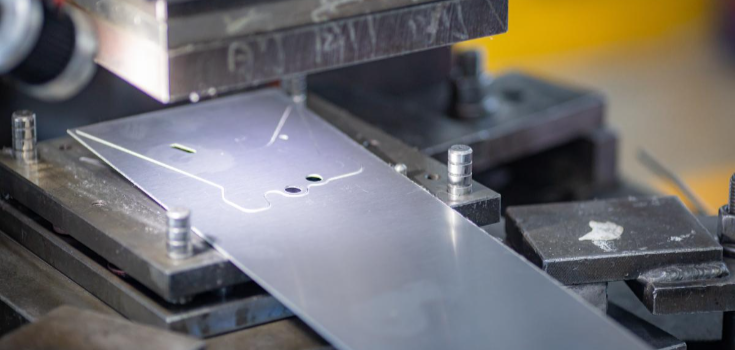

What is Compound Die Stamping?

Compound die stamping involves a single stroke of the press to produce a part. In this method, multiple operations such as cutting, punching, and bending can occur simultaneously within one die set. This approach is typically employed for simpler, flat parts requiring precision.

Advantages of Compound Die Stamping

- High precision and accuracy.

- Reduced material wastage.

- Cost-effective for small to medium production runs.

Compound die stamping is ideal for projects where precision is paramount, and the complexity of the part design is relatively low. This method ensures that each piece is uniform and meets strict specifications.

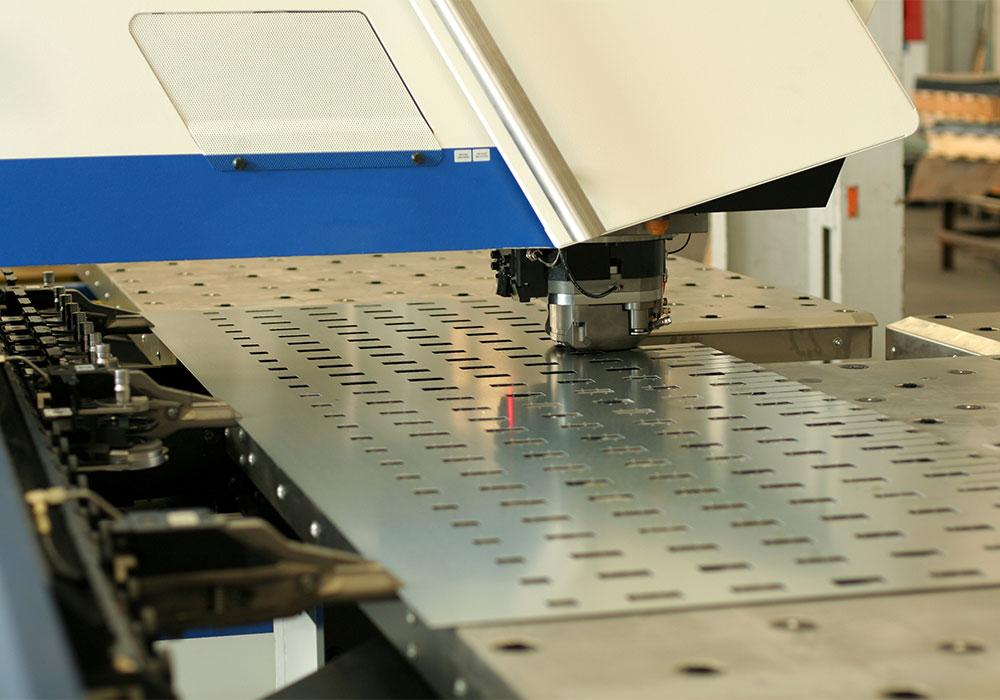

What is Progressive Die Stamping?

Progressive die stamping, on the other hand, involves a series of stations, each performing a different operation on the part as it moves through the die. This technique is best suited for complex parts that require multiple operations.

Advantages of Progressive Die Stamping

- Efficient for high-volume production.

- Capable of producing intricate parts.

- Reduced manufacturing time.

Progressive die stamping is often the preferred choice for manufacturers who need to produce large quantities of parts with intricate designs quickly and efficiently.

Comparing Compound and Progressive Die Stamping

When comparing compound die vs progressive die stamping, several factors come into play, including cost, complexity, volume, and precision requirements.

Cost Considerations

Compound die stamping is typically more cost-effective for smaller production runs due to its simplicity and lower setup costs. Progressive die stamping, although more expensive to set up, becomes cost-effective for large-scale production due to its efficiency and speed.

Complexity and Precision

For simple, flat parts requiring high precision, compound die stamping is the go-to method. In contrast, progressive die stamping excels at producing complex, multi-featured parts in a single pass through the die.

Production Volume

Manufacturers looking to produce large quantities of parts will benefit from the efficiency of progressive die stamping. It allows for continuous operation and a quicker turnaround, making it ideal for high-volume production.

Applications of Each Stamping Method

Each stamping method has its unique applications based on the requirements of the final product.

Applications of Compound Die Stamping

- Automotive components.

- Simple electrical connectors.

- Flat metal parts in consumer electronics.

Applications of Progressive Die Stamping

- Complex automotive parts.

- Intricate electronic enclosures.

- Metal parts with detailed features.

Choosing the Right Stamping Method

To choose between compound die vs progressive die stamping, manufacturers must consider the specific needs of their project, including part complexity, production volume, and precision requirements. Consulting with experts in metal stamping can provide valuable insights and recommendations.

Real-World Examples

Many industries rely on both methods to meet their diverse production needs. For instance, consumer electronics manufacturers often use compound die stamping for simpler parts, while automotive companies prefer progressive die stamping for complex components.

Conclusion

Understanding the differences between compound die vs progressive die stamping is essential for manufacturers looking to optimize their production processes. Each method has its strengths and is suited to different applications, making it important to evaluate the specific needs of each project carefully.

FAQs

- What is the main difference between compound and progressive die stamping? Compound die stamping involves a single operation per press stroke, while progressive die stamping involves multiple operations as the material moves through different stations in the die.

- Which method is more cost-effective for high-volume production? Progressive die stamping is generally more cost-effective for high-volume production due to its efficiency and speed.

- Can compound die stamping produce intricate parts? Compound die stamping is better suited for simpler, flat parts and may not be ideal for intricate designs.

For further reading on metal stamping processes, you can visit ArandaTooling for an in-depth guide.

This article contains affiliate links. We may earn a commission at no extra cost to you.