The world of manufacturing is vast and varied, with numerous processes designed to create precision parts and components. One of these processes is compound die stamping, a method that combines multiple operations into a single step. This innovative approach is particularly valuable in industries where efficiency and precision are paramount. In this article, we will explore compound die stamping explained in detail, shedding light on its mechanisms, benefits, and applications.

What is Compound Die Stamping?

Compound die stamping is a manufacturing process where a single die performs multiple operations, such as cutting and shaping, in one stroke. This efficiency makes it a popular choice for producing complex parts quickly and accurately. By utilizing a single die, manufacturers can reduce production time and costs, while maintaining high levels of precision.

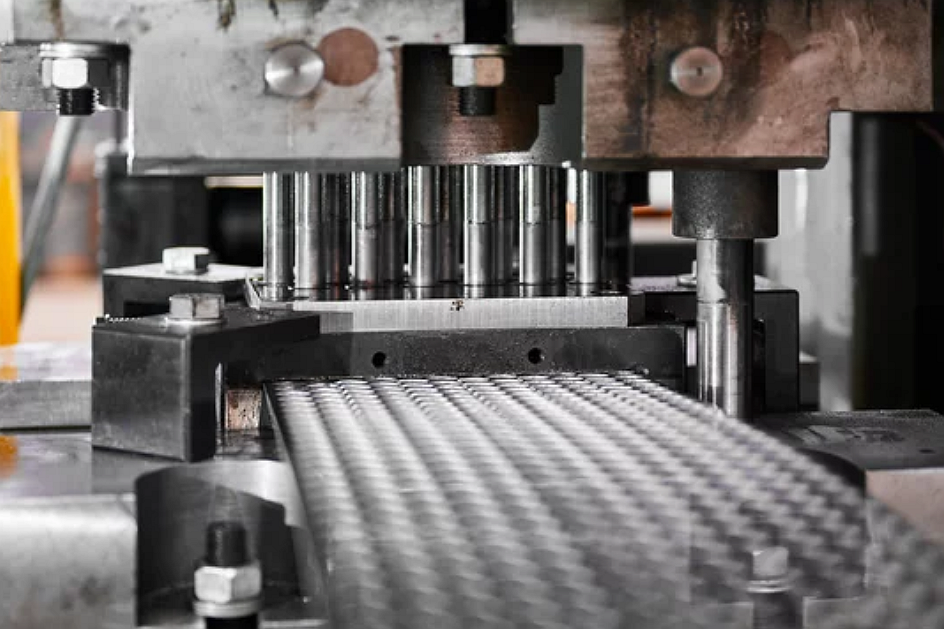

How Does Compound Die Stamping Work?

In compound die stamping, the die is designed to perform several operations simultaneously. When the press descends, the die cuts, bends, or forms the metal into the desired shape. This seamless operation is achieved through careful die design and precision engineering. The result is a high-quality part produced in a fraction of the time it would take using separate processes.

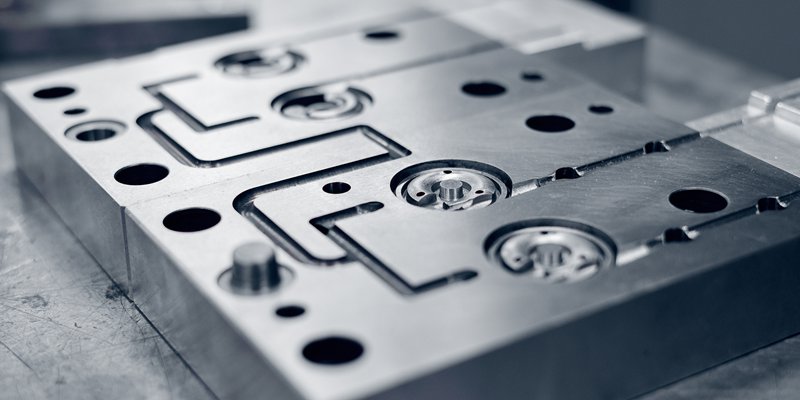

Components of a Compound Die

A typical compound die consists of several key components, including the punch, die block, and stripper plate. Each part plays a crucial role in ensuring the stamping process runs smoothly and efficiently. The punch is responsible for cutting the metal, while the die block shapes it. The stripper plate ensures the material is held securely during the process, preventing any movement that could compromise the final product.

Advantages of Compound Die Stamping

One of the primary advantages of compound die stamping is its ability to produce complex parts quickly and accurately. By combining multiple operations into a single step, manufacturers can reduce production time and costs. Additionally, this process allows for greater precision and consistency, resulting in high-quality parts that meet strict industry standards.

Applications of Compound Die Stamping

Compound die stamping is used across a variety of industries, from automotive to electronics. In the automotive sector, it is used to produce components such as brackets, clips, and fasteners. In the electronics industry, it is employed to create intricate parts for devices such as smartphones and computers. The versatility of this process makes it an invaluable tool for manufacturers looking to produce high-quality parts efficiently.

Comparison with Other Stamping Processes

While compound die stamping offers numerous benefits, it is not the only stamping process available to manufacturers. Other methods, such as progressive die stamping and transfer die stamping, offer their own advantages. Progressive die stamping involves a series of dies that gradually shape the metal, while transfer die stamping uses a series of stations to move the part through the process. Each method has its own strengths and weaknesses, and the choice of process will depend on the specific requirements of the project.

Challenges in Compound Die Stamping

Despite its advantages, compound die stamping does present some challenges. Designing a die capable of performing multiple operations requires a high level of expertise and precision engineering. Additionally, the initial cost of creating a compound die can be higher than other methods. However, these challenges are often offset by the efficiency and cost savings achieved during production.

Future of Compound Die Stamping

As technology continues to advance, the future of compound die stamping looks promising. Innovations in materials and manufacturing techniques are opening up new possibilities for this process, allowing manufacturers to create even more complex and precise parts. As industries continue to demand high-quality components at lower costs, compound die stamping is poised to play an increasingly important role in the manufacturing landscape.

Conclusion

In conclusion, compound die stamping is a highly efficient and precise manufacturing process that offers numerous benefits to industries around the world. By combining multiple operations into a single step, manufacturers can produce high-quality parts quickly and cost-effectively. As technology continues to evolve, the potential for compound die stamping is only set to grow, making it an invaluable tool for the future of manufacturing.

FAQ

What industries use compound die stamping?

Compound die stamping is used in a variety of industries, including automotive, electronics, and consumer goods. Its ability to produce complex parts quickly and accurately makes it a popular choice for manufacturers.

What are the main components of a compound die?

A typical compound die consists of several key components, including the punch, die block, and stripper plate. Each part plays a crucial role in ensuring the stamping process runs smoothly and efficiently.

How does compound die stamping compare to other stamping processes?

While compound die stamping offers numerous benefits, it is not the only stamping process available. Other methods, such as progressive die stamping and transfer die stamping, offer their own advantages. The choice of process will depend on the specific requirements of the project.

This article contains affiliate links. We may earn a commission at no extra cost to you.