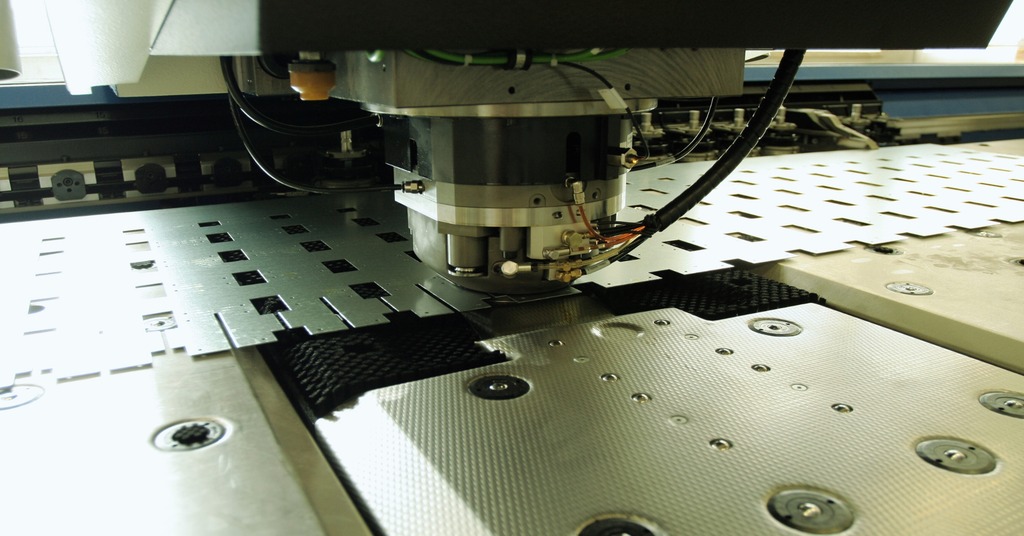

In the world of industrial manufacturing, the role of stamping dies is crucial. These tools shape and cut materials into specific forms, making them fundamental in creating various products. The use of coatings for stamping dies has become a significant aspect of ensuring their longevity and efficiency. This article delves into the importance of these coatings, the types available, and their impact on die performance.

Importance of Coatings in Stamping Dies

Stamping dies endure immense pressure and wear during operations. To combat this, manufacturers apply specific coatings to enhance their durability. These coatings act as a protective layer, reducing friction and preventing wear and tear. By minimizing these issues, the lifespan of the dies increases, which in turn boosts productivity and reduces costs.

Types of Coatings for Stamping Dies

There are several types of coatings used for stamping dies, each offering unique benefits. Some of the most common include:

- TiN (Titanium Nitride): Known for its hardness and wear resistance, TiN is a popular choice for many manufacturers.

- TiCN (Titanium Carbonitride): Offers greater hardness than TiN, making it suitable for more demanding applications.

- CrN (Chromium Nitride): Provides excellent corrosion resistance, making it ideal for environments exposed to moisture.

- AlTiN (Aluminum Titanium Nitride): Withstands high temperatures, making it perfect for high-speed operations.

How Coatings Enhance Die Performance

Applying coatings to stamping dies results in numerous performance enhancements. Firstly, the coatings reduce friction between the die and the material, leading to smoother operations and less heat generation. Secondly, the coatings protect the die from abrasive wear, which is a common cause of damage in stamping processes. Lastly, the coatings can enhance the die’s ability to resist corrosion and oxidation, especially in harsh environments.

Cost Implications of Using Coated Stamping Dies

While the initial investment in coated dies may be higher, the long-term benefits are substantial. Coated dies typically require less maintenance, reducing downtime and repair costs. Additionally, their extended lifespan means fewer replacements, which further cuts costs. By reducing these expenses, manufacturers can allocate resources to other areas, enhancing overall productivity.

Choosing the Right Coating for Your Needs

Selecting the appropriate coating for your stamping dies depends on several factors. These include the type of material being stamped, the operating conditions, and the specific demands of the application. Consulting with a specialist can help determine the most suitable coating, ensuring optimal performance and cost-effectiveness.

Real-World Applications of Coated Stamping Dies

Coated stamping dies are used in various industries, from automotive to electronics. For example, in the automotive sector, these dies are essential for producing precise components like body panels and engine parts. In electronics, they help create intricate components required for devices. By applying coatings, manufacturers can ensure consistent quality and reliability in their products.

Environmental Impact of Coated Stamping Dies

Using coated dies also has environmental benefits. By extending the life of the dies and reducing the need for frequent replacements, manufacturers can decrease their carbon footprint. Additionally, some coatings are designed to be environmentally friendly, further supporting sustainable manufacturing practices.

Challenges in Implementing Coated Stamping Dies

Despite their benefits, there are challenges in implementing coated dies. These include the initial cost and the need for specialized equipment for application. However, with advancements in technology, these barriers are gradually being overcome, making coated dies more accessible to manufacturers.

The Future of Coatings for Stamping Dies

The future of coatings for stamping dies looks promising, with ongoing research and development. Innovations aim to create even more durable and efficient coatings, further enhancing the performance of stamping dies. As technology advances, manufacturers can expect to see more cost-effective and environmentally friendly solutions.

Quality Control in Coated Stamping Dies

Ensuring the quality of coated dies is vital for optimal performance. Manufacturers must implement stringent quality control measures to verify the integrity and effectiveness of the coatings. This includes regular inspections and testing to detect any potential issues early on.

Training for Operators Using Coated Stamping Dies

Operators play a crucial role in the successful implementation of coated dies. Providing comprehensive training ensures they understand the benefits and limitations of the coatings, enabling them to maximize the dies’ performance. Proper training also helps prevent damage and extends the life of the dies.

Industry Standards for Coated Stamping Dies

Adhering to industry standards is essential for ensuring the reliability and effectiveness of coated dies. These standards provide guidelines for the application and maintenance of the coatings, ensuring consistent quality across the industry.

Conclusion

In conclusion, coatings for stamping dies play a vital role in enhancing the performance and lifespan of these essential tools. By understanding the benefits and challenges of using coated dies, manufacturers can make informed decisions that improve productivity and reduce costs. As technology advances, the future of coated stamping dies looks bright, promising even greater innovations and improvements.

Frequently Asked Questions

What are the main benefits of using coated stamping dies?

The main benefits include increased durability, reduced wear and tear, lower maintenance costs, and improved performance.

How do I choose the right coating for my stamping dies?

Consider factors such as the material being stamped, operating conditions, and specific application demands. Consulting with a specialist can help determine the best coating for your needs.

Are there environmental benefits to using coated stamping dies?

Yes, coated dies can reduce the need for replacements, decreasing the carbon footprint. Additionally, some coatings are environmentally friendly, supporting sustainable manufacturing practices.

This article contains affiliate links. We may earn a commission at no extra cost to you.