In today’s rapidly evolving manufacturing landscape, CNC stamping technology has emerged as a cornerstone of innovation and efficiency. This groundbreaking technology is revolutionizing the way industrial manufacturers operate, offering unprecedented precision and versatility. In this article, we delve into the intricacies of CNC stamping technology, exploring its applications, benefits, and impact on the industry. As we navigate through this technological marvel, you’ll discover why it has become a pivotal component in modern manufacturing.

Understanding CNC Stamping Technology

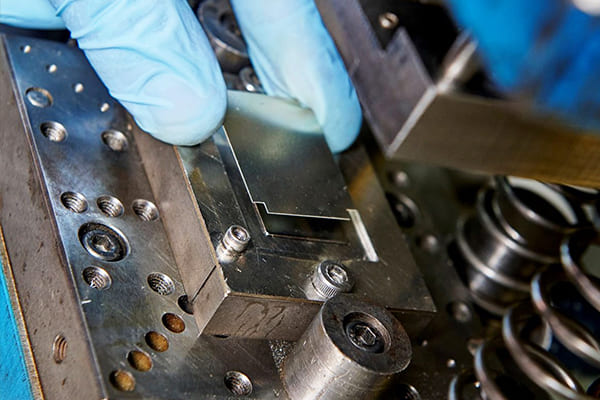

CNC stamping technology combines computer numerical control (CNC) with traditional stamping methods to create intricate designs and components. This technology leverages advanced software to control the stamping machine’s movements, ensuring precise and consistent results. Whether it’s forming metal sheets into complex shapes or creating intricate patterns, CNC stamping technology excels in delivering accuracy and efficiency.

The Core Components of CNC Stamping

At the heart of CNC stamping technology are several key components:

- Stamper: The machine responsible for applying force to the material, shaping it according to the programmed design.

- Die: A custom-designed tool that determines the final shape and features of the stamped product.

- Control System: The software that guides the machine’s movements, ensuring precision and accuracy.

Applications of CNC Stamping Technology

CNC stamping technology finds applications across various industries, making it a versatile tool for manufacturers. From automotive and aerospace to electronics and consumer goods, the possibilities are endless. This technology is particularly useful in producing components with complex geometries, where traditional methods may fall short.

Automotive Industry

In the automotive sector, CNC stamping technology plays a crucial role in manufacturing parts such as brackets, panels, and structural components. The precision and speed offered by CNC stamping enable manufacturers to meet the demands of high-volume production while maintaining quality standards.

Aerospace Industry

The aerospace industry benefits from CNC stamping technology’s ability to produce lightweight yet durable components. From intricate airframe parts to engine components, CNC stamping ensures the highest level of accuracy and reliability, contributing to the safety and performance of aircraft.

Advantages of CNC Stamping Technology

The adoption of CNC stamping technology brings numerous advantages to industrial manufacturers:

Precision and Accuracy

One of the standout features of CNC stamping technology is its ability to deliver unparalleled precision. The computer-controlled system ensures that each stamped component meets exact specifications, reducing the risk of errors and rework.

Cost Efficiency

By automating the stamping process, manufacturers can significantly reduce labor costs and material waste. CNC stamping technology optimizes material usage, minimizing scrap and maximizing yield, ultimately leading to cost savings.

Flexibility and Versatility

CNC stamping technology offers unmatched flexibility, allowing manufacturers to switch between different designs and configurations with ease. This adaptability is especially valuable in industries where customization and rapid prototyping are essential.

The Future of CNC Stamping Technology

As technology continues to advance, the future of CNC stamping looks promising. Innovations in software and machine capabilities are expected to further enhance the efficiency and capabilities of this technology. Manufacturers can anticipate even greater levels of automation, integration with artificial intelligence, and improved sustainability practices.

Integration with IoT and AI

The integration of the Internet of Things (IoT) and artificial intelligence (AI) with CNC stamping technology is set to revolutionize the manufacturing process. These technologies enable real-time monitoring, predictive maintenance, and data-driven decision-making, leading to increased productivity and reduced downtime.

Sustainability Initiatives

As environmental concerns gain prominence, CNC stamping technology is increasingly being aligned with sustainability initiatives. Manufacturers are exploring ways to reduce energy consumption, minimize waste, and incorporate eco-friendly materials, ensuring a greener future for the industry.

Challenges and Considerations

While CNC stamping technology offers numerous benefits, it also presents certain challenges that manufacturers must address:

Initial Investment

The cost of acquiring CNC stamping equipment and software can be significant. Manufacturers need to carefully evaluate the return on investment and consider the long-term benefits before committing to this technology.

Skill Development

Operating CNC stamping machines requires specialized skills and training. Manufacturers must invest in workforce development to ensure that their employees are proficient in using the technology effectively.

Conclusion

In conclusion, CNC stamping technology has become a game-changer in the manufacturing industry. Its precision, efficiency, and versatility have transformed the way components are produced, enabling manufacturers to meet the demands of modern markets. As the technology continues to evolve, it holds the promise of even greater advancements, paving the way for a more sustainable and innovative future.

FAQs

What is CNC stamping technology?

CNC stamping technology combines computer numerical control with traditional stamping methods to create precise and intricate components.

What are the main benefits of CNC stamping?

The main benefits of CNC stamping include precision, cost efficiency, and flexibility, making it ideal for various industries.

How does CNC stamping impact the automotive industry?

In the automotive industry, CNC stamping technology enables the production of high-quality components with precision and speed, enhancing overall efficiency.

For more detailed insights on the differences between metal punching and stamping, you can visit RapidDirect. Additionally, to understand how a stamping press works, Phoenix Specialty offers a comprehensive guide.

This article contains affiliate links. We may earn a commission at no extra cost to you.