When choosing stamping press suppliers, making the right decision is crucial to ensure efficiency and quality in your manufacturing process. The success of your operations heavily depends on the capabilities and reliability of your suppliers. In this guide, we will explore various aspects to consider when selecting a supplier, ensuring that you make an informed decision that aligns with your business goals.

Understanding the Importance of Stamping Presses

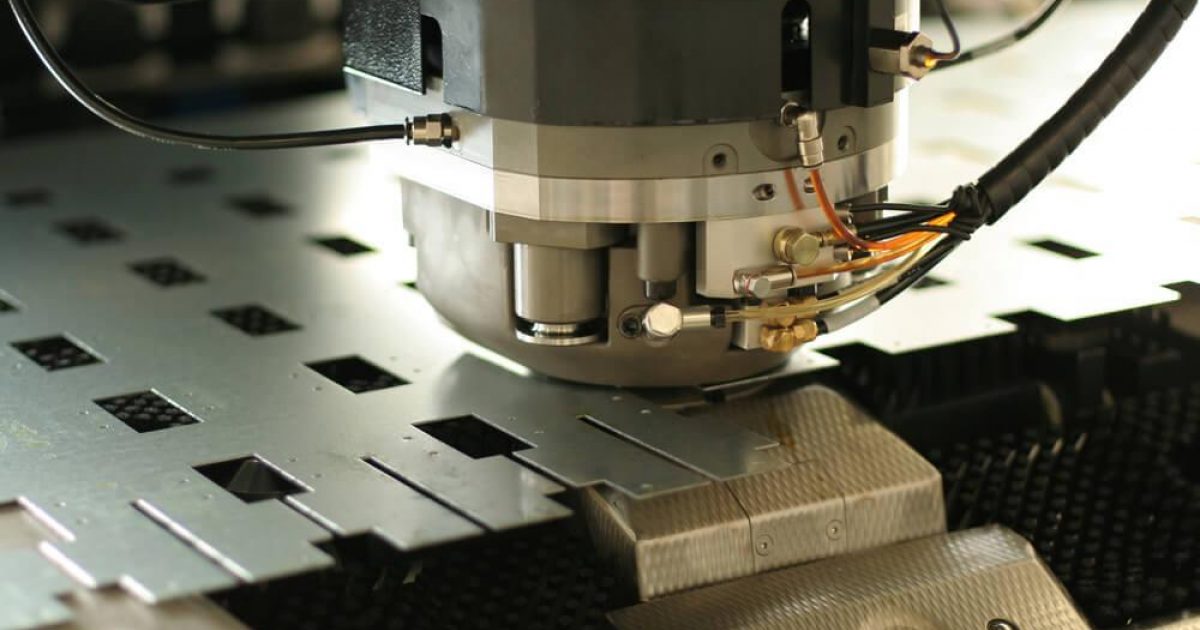

Stamping presses play a vital role in the manufacturing industry, especially in sectors such as automotive, electronics, and appliance manufacturing. They are used to shape and cut metal sheets into specific forms, enabling mass production of components with precision and speed. To learn more about the intricate workings of a stamping press, you can visit this detailed article.

Key Considerations When Choosing Stamping Press Suppliers

Assessing Supplier Reputation

The reputation of a supplier is a key indicator of their reliability and quality. Conduct thorough research to gather feedback from other manufacturers who have worked with potential suppliers. Online reviews and industry forums can provide valuable insights.

Evaluating Product Quality

Quality is paramount in manufacturing. Assess the quality of the stamping presses offered by suppliers. Consider factors such as durability, precision, and ease of maintenance. Opt for suppliers who adhere to stringent quality control standards.

Considering Technological Advancements

Technological innovation is a driving force in the industry. Ensure that your supplier is up-to-date with the latest advancements. Modern presses come with features that enhance efficiency and safety. For insights on new vs. used equipment, check out our guide on new vs. used stamping equipment.

Supplier Capabilities

Production Capacity

Evaluate the production capacity of potential suppliers. They should be able to meet your demand consistently, especially during peak production periods. A supplier with scalable capacity can adapt to your growing needs.

Customization Options

Every manufacturing process has unique requirements. A supplier offering customization options can tailor their products to suit your specific needs, providing a competitive edge in your operations.

Logistics and Delivery

Timely delivery is critical in maintaining a smooth production flow. Assess the logistics capabilities of your supplier. They should have a robust delivery network to ensure that your presses arrive on time.

After-Sales Support

After-sales support is essential for addressing any issues that may arise post-purchase. Opt for suppliers who offer comprehensive support packages, including training, maintenance, and repair services. For additional insights, explore our article on stamping machine operator training.

Cost Considerations

Comparing Prices

While cost is a significant factor, it should not be the sole determinant. Compare prices among different suppliers, but also consider the value offered in terms of quality, support, and customization.

Long-term Investment

Consider the long-term benefits of investing in high-quality stamping presses. A more expensive initial investment may result in lower maintenance costs and higher productivity over time, offering better value.

Environmental and Safety Considerations

Compliance with Regulations

Ensure that your supplier complies with all relevant environmental and safety regulations. This not only safeguards your operations but also contributes to sustainable manufacturing practices.

Safety Features

Modern presses should come equipped with safety features to protect operators and prevent accidents. When evaluating suppliers, prioritize those who prioritize safety in their equipment design.

Building a Strong Supplier Relationship

Establishing a strong relationship with your supplier can lead to mutual benefits in the long run. Open communication and collaboration can foster innovation and continuous improvement in your manufacturing processes.

FAQ

What are the key factors in choosing stamping press suppliers?

Key factors include supplier reputation, product quality, technological advancements, production capacity, customization options, logistics, after-sales support, cost considerations, and compliance with regulations.

How do technological advancements affect stamping presses?

Technological advancements enhance the efficiency, precision, and safety of stamping presses, making them more reliable and capable of meeting complex manufacturing demands.

Why is supplier reputation important?

A supplier’s reputation is indicative of their reliability and the quality of their products and services. A positive reputation ensures that you are partnering with a trusted and proven supplier.

This article contains affiliate links. We may earn a commission at no extra cost to you.