In the rapidly evolving world of industrial manufacturing, the integration of CAD CAM in stamping die design has become a pivotal advancement. The use of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) has revolutionized how stamping dies are designed, enhancing precision, efficiency, and productivity. This technological evolution is not just a trend, but a necessity for modern manufacturers aiming to stay competitive.

The implementation of CAD CAM in stamping die design is particularly beneficial in industries such as automotive, aerospace, and consumer electronics, where precision and efficiency are paramount. By streamlining the design and manufacturing processes, companies can reduce costs, improve quality, and accelerate time-to-market.

The Role of CAD CAM in Modern Manufacturing

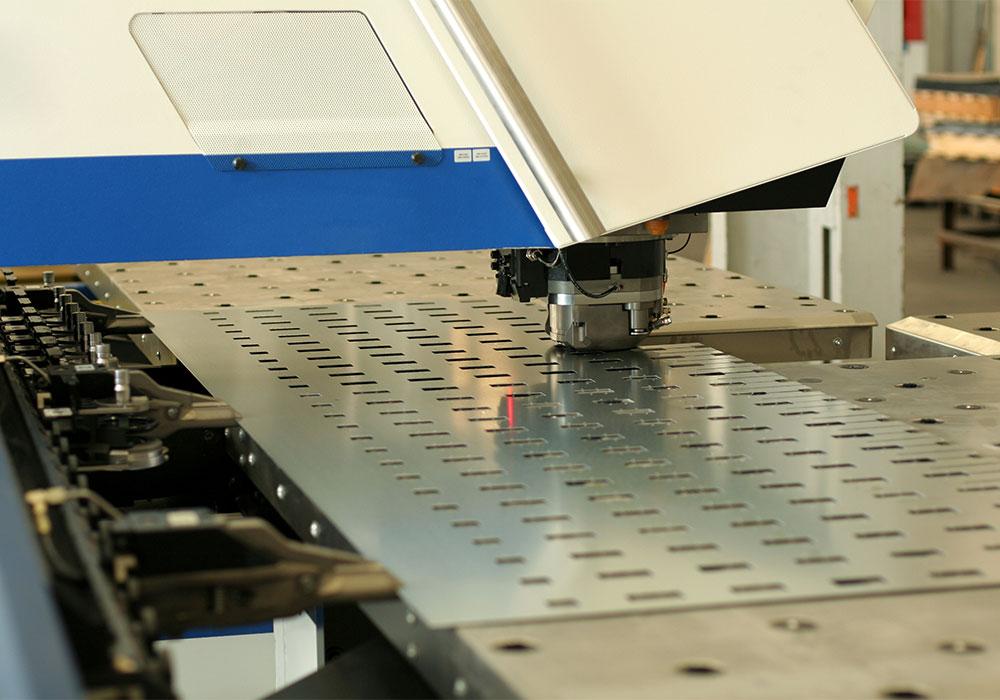

Understanding the role of CAD CAM in modern manufacturing is crucial for appreciating its impact on stamping die design. CAD allows engineers to create detailed 3D models of stamping dies, ensuring that every dimension and specification is meticulously detailed. CAM, on the other hand, uses these models to control machinery and automate the production process.

This integration facilitates a seamless transition from design to production, minimizing errors and ensuring a high degree of accuracy. By using CAD CAM, manufacturers can also simulate and analyze different aspects of the design, such as stress points and material flow, before actual production begins.

Benefits of Using CAD CAM in Stamping Die Design

The benefits of employing CAD CAM in stamping die design are numerous. Firstly, it significantly reduces the time required to design and manufacture dies. This time efficiency translates into faster project turnaround times, which is a crucial advantage in competitive markets.

Moreover, the precision offered by CAD CAM systems leads to higher quality products. With accurate designs and automated manufacturing processes, the margin for error is drastically reduced. This precision is particularly important in industries like medical device metal stamping, where even the slightest imperfection can have significant consequences.

Challenges in Implementing CAD CAM Systems

While the advantages are clear, implementing CAD CAM systems is not without its challenges. The initial cost of software and hardware can be prohibitive for smaller companies. Furthermore, there is a learning curve associated with mastering these technologies, necessitating investment in training and development.

Another challenge is the integration of CAD CAM systems with existing processes and tooling. Companies must be prepared to overhaul their current systems to fully benefit from this technology. This integration requires careful planning and execution to ensure minimal disruption to production schedules.

Overcoming the Challenges

To overcome these challenges, manufacturers can adopt a phased approach to implementation. This involves gradually integrating CAD CAM systems into their operations, allowing time for employees to adapt and for any issues to be addressed without significantly impacting production.

Additionally, companies can leverage stamping machine operator training programs to upskill their workforce. By investing in training, manufacturers can ensure that their employees are equipped to maximize the benefits of CAD CAM technology.

Impact of CAD CAM on Product Quality

The impact of CAD CAM on product quality cannot be overstated. With precise control over the design and manufacturing processes, the consistency and repeatability of the final products are greatly enhanced. This quality assurance is vital in industries where product specifications are stringent.

Furthermore, CAD CAM allows for continuous quality control throughout the production process. By integrating real-time monitoring and feedback mechanisms, manufacturers can identify and rectify any discrepancies immediately, ensuring that the end product meets all quality standards.

Quality Control Systems

Implementing robust quality control systems is essential for maximizing the benefits of CAD CAM. These systems should be designed to monitor every stage of the production process, from initial design to final inspection. By doing so, manufacturers can maintain high standards of quality and reduce the likelihood of defects.

Future Trends in CAD CAM Technology

As technology continues to advance, so too will the capabilities of CAD CAM systems. One of the most exciting trends is the integration of artificial intelligence (AI) and machine learning into CAD CAM software. These technologies have the potential to further enhance the efficiency and effectiveness of stamping die design.

AI algorithms can analyze vast amounts of data to optimize designs and predict potential issues before they occur. This predictive capability can significantly reduce development times and improve the quality of the final product.

Conclusion

In conclusion, the integration of CAD CAM in stamping die design is a transformative development in industrial manufacturing. By enhancing precision, efficiency, and product quality, CAD CAM systems are helping manufacturers meet the demands of modern markets. While challenges exist, the benefits far outweigh the drawbacks, making CAD CAM an essential tool for any forward-thinking manufacturer.

As the industry continues to evolve, manufacturers who embrace CAD CAM technology will be well-positioned to lead the way in innovation and quality. For more information on metal stamping, you can visit this resource.

FAQs

What is CAD CAM in stamping die design?

CAD CAM refers to the use of computer-aided design and computer-aided manufacturing systems to design and produce stamping dies with high precision and efficiency.

Why is CAD CAM important in industrial manufacturing?

It enhances the precision, efficiency, and quality of the manufacturing process, reducing time and costs while improving the quality of the final product.

What are the challenges of implementing CAD CAM systems?

Challenges include high initial costs, the learning curve associated with new technologies, and the need to integrate these systems with existing processes.

This article contains affiliate links. We may earn a commission at no extra cost to you.