The art of metal stamping is a critical component in the world of industrial manufacturing. As manufacturers strive for efficiency and precision, understanding the best practices in metal stamping becomes crucial. This article delves into the essential practices that industrial manufacturers need to consider to enhance their stamping processes.

Understanding Metal Stamping

Metal stamping is a process that involves the use of a press to shape or cut metal into a desired form. The technique has been a cornerstone of manufacturing for decades, providing a cost-effective way to produce high volumes of identical components. To learn more about the basics of metal stamping, visit ESICT.

Importance of Quality Material Selection

Choosing the right material is the first step in ensuring successful metal stamping. The material’s properties, such as thickness, ductility, and strength, can significantly impact the outcome of the stamping process. Manufacturers should prioritize materials that align with their end product’s requirements.

Material Properties and Their Impact

Understanding the properties of different metals helps in selecting the right metal stamping material. For instance, aluminum is lightweight and corrosion-resistant, making it ideal for automotive parts, while stainless steel offers durability for kitchen appliances.

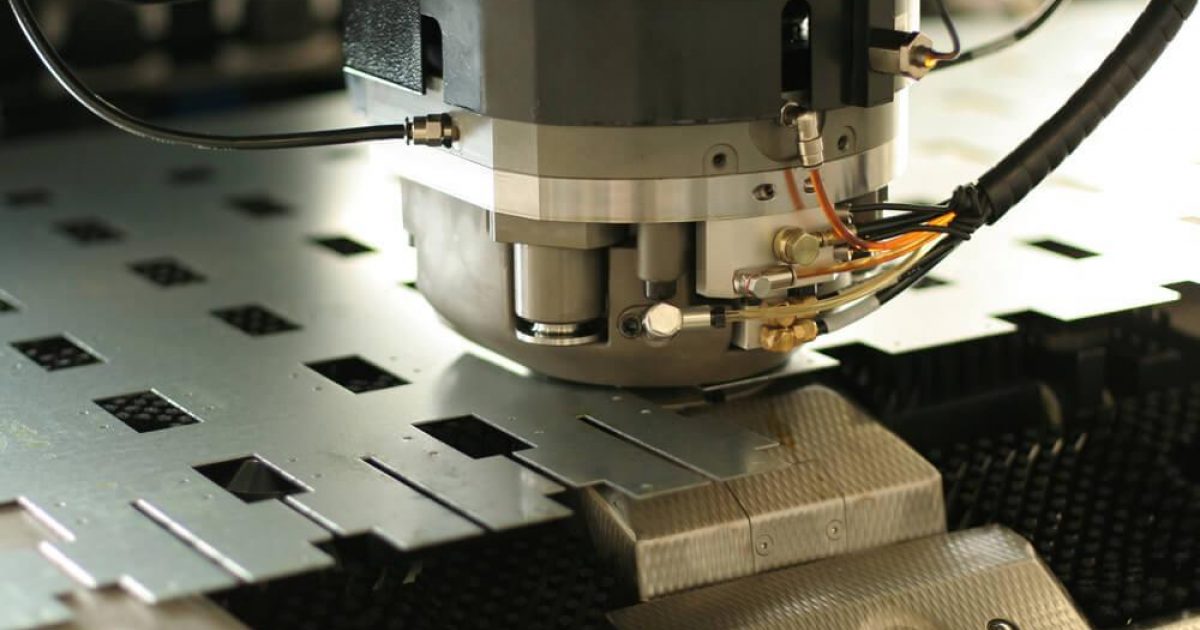

Precision in Tool and Die Design

The design of tools and dies is a pivotal aspect of the metal stamping process. Precision in these designs ensures that the stamped parts meet the desired specifications and reduces the likelihood of defects.

Role of Computer-Aided Design (CAD)

Utilizing CAD software in the design of tools and dies enhances precision and allows for adjustments before the physical production begins. This practice minimizes errors and optimizes the efficiency of the stamping process.

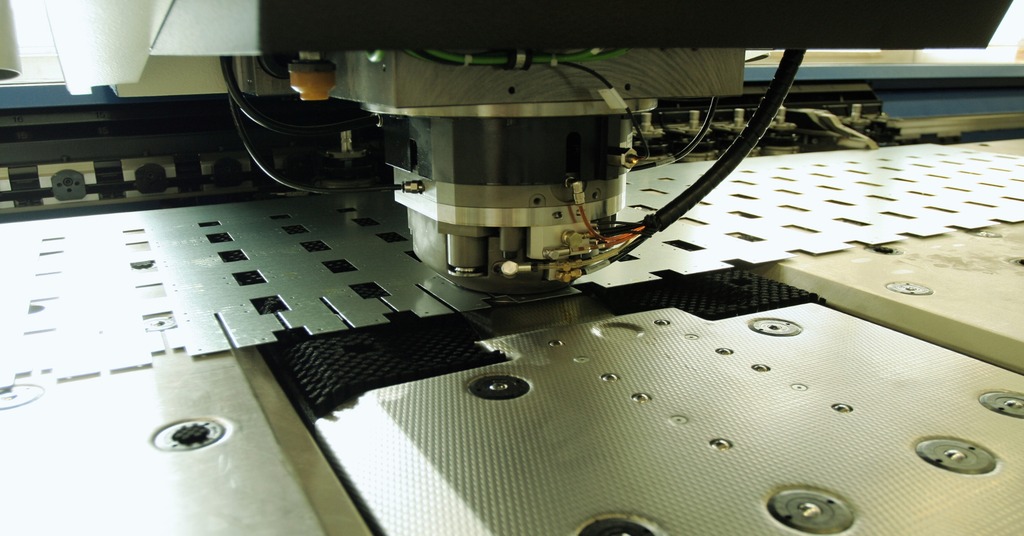

Implementing Advanced Technologies

The integration of advanced technologies, such as automation and robotics, can significantly enhance the metal stamping process. These technologies improve speed, accuracy, and safety in the manufacturing environment.

Automation in Metal Stamping

Automation reduces the reliance on manual labor and increases the consistency of the stamped products. Implementing robotic systems can streamline operations and improve overall productivity.

Regular Maintenance of Equipment

Regular maintenance of stamping equipment is crucial to avoid unexpected downtimes and ensure consistent product quality. Scheduled inspections and timely repairs can prolong the lifespan of the machinery.

Checklist for Maintenance

- Inspect the condition of tools and dies regularly.

- Ensure lubrication systems are functioning correctly.

- Check for wear and tear on moving parts.

For more information on maintaining metalwork equipment, check out our guide on Metal Garden Art.

Employee Training and Safety

Investing in employee training is vital for a successful metal stamping operation. Well-trained staff can operate machinery more efficiently and safely, reducing the risk of accidents and improving productivity.

Safety Protocols

Implementing strict safety protocols protects workers and equipment. Equip employees with the necessary safety gear and ensure they are familiar with the operational procedures.

Monitoring and Quality Control

Quality control is an integral part of the metal stamping process. Monitoring the production line helps identify defects early and ensures that final products meet the required standards.

Utilizing Quality Assurance Tools

Implementing tools like Statistical Process Control (SPC) helps in monitoring the manufacturing process and maintaining high-quality output.

Cost Management Strategies

Efficient cost management is essential for maintaining profitability in metal stamping. Manufacturers should focus on optimizing resource use and reducing waste.

Lean Manufacturing Practices

Adopting lean manufacturing practices minimizes waste and maximizes resource utilization. This approach helps in reducing costs and improving overall efficiency.

Environmental Considerations

Environmental sustainability is becoming increasingly important in manufacturing. Implementing eco-friendly practices in metal stamping can reduce the environmental impact and enhance the company’s reputation.

Recycling and Waste Management

Recycling scrap metal and managing waste effectively can significantly reduce the environmental footprint of a manufacturing operation.

Adapting to Market Trends

Staying abreast of market trends is crucial for manufacturers to remain competitive. Adapting to new technologies and consumer demands can open new opportunities for growth.

Developing Innovative Products

Innovating product designs and exploring new markets can keep manufacturers ahead of the competition. Embracing change is key to long-term success.

Conclusion

Mastering the best practices in metal stamping is essential for industrial manufacturers aiming for excellence. By understanding material selection, tool design, technological advancements, and employee training, manufacturers can enhance their processes and produce high-quality components efficiently.

FAQ

What are the primary materials used in metal stamping?

Common materials include aluminum, stainless steel, copper, and brass, each offering unique properties for different applications.

How does automation affect metal stamping?

Automation improves efficiency, reduces errors, and enhances safety in the metal stamping process.

Why is regular equipment maintenance important?

Regular maintenance prevents unexpected downtimes and ensures machinery operates at peak efficiency.

This article contains affiliate links. We may earn a commission at no extra cost to you.