The field of tool and die making is experiencing remarkable transformations with the advent of automation. In this article, we explore how automation in tool and die making is revolutionizing manufacturing processes, improving efficiency, and reducing costs. As industries seek to maintain competitiveness, understanding the role of automation is crucial for success.

Understanding Tool and Die Making

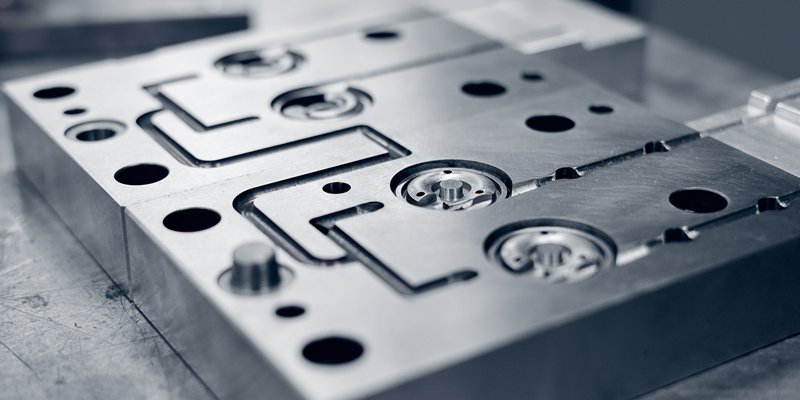

Before diving into automation, it’s essential to understand what tool and die making involves. This process is foundational in manufacturing, providing the necessary tools for shaping, cutting, and forming materials into specific designs. The quality and precision of these tools directly impact the efficiency of production lines.

The Role of Automation

Automation introduces advanced machinery and software to perform tasks that traditionally required manual input. In tool and die making, automation enhances precision, reduces human error, and speeds up production. This shift is particularly beneficial in industries demanding high-volume production with minimal variation.

Benefits of Automation in Tool and Die Making

Increased Efficiency

One of the primary advantages of automation is increased efficiency. Automated systems can operate continuously without fatigue, ensuring consistent production levels. This maximizes productivity while minimizing downtime.

Cost Reduction

By implementing automation, companies can significantly reduce labor costs. Machines can perform repetitive tasks with greater accuracy, reducing the need for extensive manual labor. This not only lowers costs but also improves the overall quality of the final product.

Enhanced Precision

Precision is critical in tool and die making. Automation allows for meticulous control over manufacturing processes, ensuring that each product meets stringent specifications. This is particularly vital in industries such as aerospace and automotive, where even minor deviations can have significant consequences.

Challenges in Implementing Automation

Initial Investment

The transition to automation requires a substantial initial investment. Purchasing and integrating automated systems can be costly, especially for small to medium-sized enterprises. However, the long-term benefits often outweigh the initial expenses.

Workforce Adaptation

Another challenge is adapting the workforce to new technologies. Employees must be trained to work alongside automated systems, requiring time and resources. Companies need to prioritize training programs to ensure a smooth transition.

Real-World Applications

Automotive Industry

The automotive industry is a prime example of successful automation in tool and die making. Automated systems streamline the production of complex components, improving both speed and quality. This industry benefits significantly from reduced production times and enhanced safety measures.

Consumer Electronics

In consumer electronics, automation ensures the precision needed for intricate designs. Consistency in production is vital to meet high consumer demand, and automated systems deliver with unparalleled accuracy.

Medical Devices

The medical device sector relies on automation for the production of critical components. High precision and reliability are non-negotiable, and automated systems excel in delivering these qualities.

Future Trends

Integration with AI

The future of automation in tool and die making lies in the integration with artificial intelligence. AI-driven systems can learn and adapt, further enhancing manufacturing processes and minimizing errors.

Sustainability

Sustainability is becoming a focal point in manufacturing. Automation systems are being designed to minimize waste and energy consumption, aligning with global environmental goals.

Conclusion

In conclusion, automation in tool and die making is revolutionizing the manufacturing industry. By increasing efficiency, reducing costs, and enhancing precision, automation is paving the way for a more competitive and sustainable future. Companies that embrace these advancements will be well-positioned to thrive in the evolving industrial landscape.

FAQs

What is tool and die making?

Tool and die making involves creating tools used for manufacturing processes, such as shaping, cutting, and forming materials.

How does automation benefit tool and die making?

Automation improves efficiency, reduces costs, and enhances precision in tool and die making processes.

What are the challenges of adopting automation?

The main challenges include the initial investment and the need for workforce adaptation to new technologies.

For more insights on metal stamping, visit What is Metal Stamping? and explore our related articles on consumer electronics stamping and operator training.

This article contains affiliate links. We may earn a commission at no extra cost to you.