In the modern manufacturing world, automatic metal stamping lines have emerged as a revolutionary process, transforming the way industries operate. By automating the stamping process, these lines offer numerous benefits including improved efficiency, precision, and cost-effectiveness. With industries continuously seeking ways to enhance productivity and maintain competitive edges, understanding the intricacies of automatic metal stamping lines can provide significant advantages.

What Are Automatic Metal Stamping Lines?

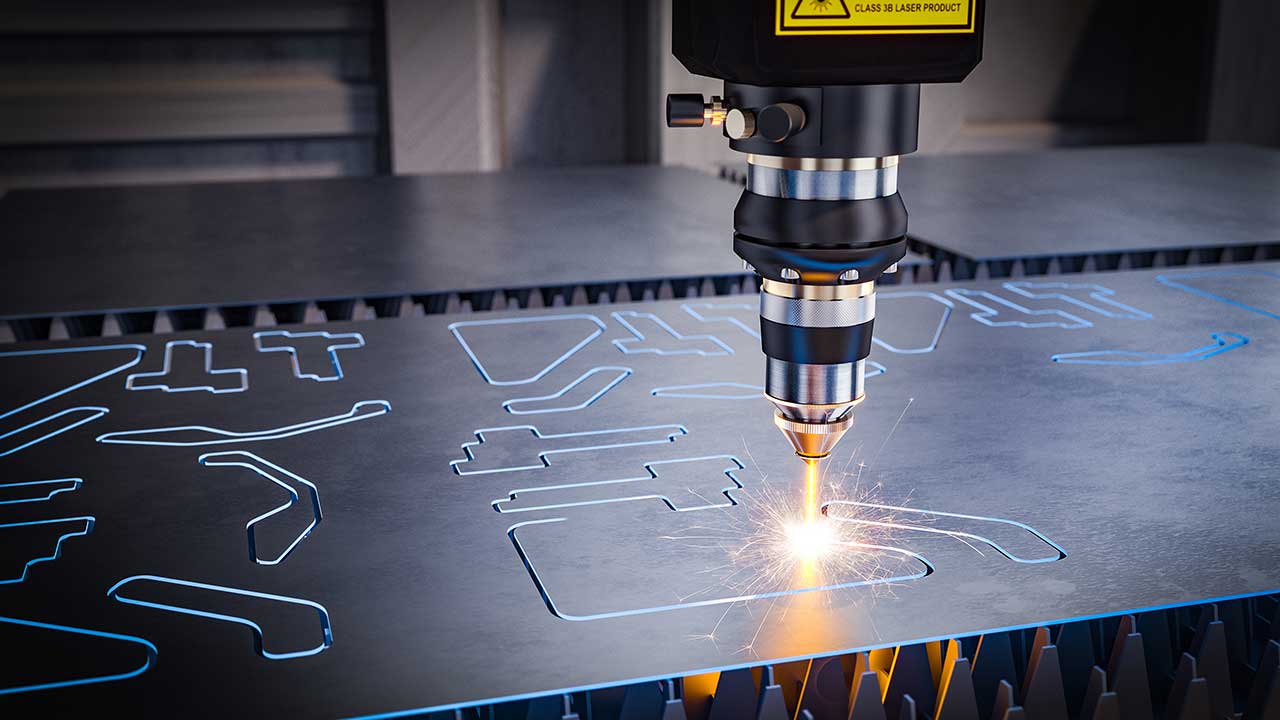

Automatic metal stamping lines are integrated systems designed to fabricate metal parts with high precision and speed. These lines consist of a sequence of machines and tools that automate the process of stamping, which involves shaping or cutting metal using a press machine. The automation within these lines minimizes human intervention, thereby reducing errors and increasing production speed.

The Evolution of Metal Stamping

The journey of metal stamping dates back to the 19th century. However, it was only with the advent of technology that metal stamping evolved into the automated systems we see today. Initially, stamping was a labor-intensive process, but technological advancements have now made it possible to automate almost every aspect of this process.

From Manual to Automatic

Historically, metal stamping was a manual task, requiring skilled labor to operate the machines. The introduction of automation in metal stamping has transformed this narrative. Automation has brought about significant improvements in terms of speed, accuracy, and consistency, which manual processes could not achieve.

Components of Automatic Metal Stamping Lines

An automatic metal stamping line comprises several key components, each playing a critical role in the overall process. These include:

Feeders

Feeders are responsible for providing continuous metal strips to the stamping press. They ensure that the metal is accurately positioned for each stamping operation.

Stamping Press

The stamping press is the core component of the line. It applies force to the metal, shaping or cutting it as required. For more detail on how a stamping press works, you can visit this external resource.

Die

The die is a specialized tool used within the press to shape the metal. It is customized based on the specific requirements of the product being manufactured.

Benefits of Automatic Metal Stamping Lines

The introduction of automation in metal stamping has brought about numerous benefits:

Increased Efficiency

Automated systems can operate continuously without fatigue, leading to higher production rates compared to manual processes.

Enhanced Precision

Automation reduces the likelihood of human error, ensuring that each part is manufactured to exact specifications.

Cost-Effectiveness

While the initial investment in automated systems can be high, the long-term savings in labor costs and increased production efficiency make them a cost-effective choice.

Applications of Automatic Metal Stamping

Automatic metal stamping lines are used across various industries, including automotive, electronics, and medical device manufacturing. For instance, in the medical sector, precision is paramount, and automated stamping ensures that components meet stringent standards. Learn more about its application in the medical field at this link.

Challenges in Implementing Automatic Metal Stamping Lines

Despite their advantages, implementing automatic metal stamping lines comes with its set of challenges:

High Initial Cost

The initial investment for setting up an automated line can be substantial, which can be a deterrent for some businesses.

Maintenance and Technical Issues

Automated systems require regular maintenance and technical expertise to ensure smooth operation.

Future Trends in Metal Stamping

The future of automatic metal stamping lines looks promising, with trends pointing towards more advanced technologies such as AI and IoT integration. These advancements are expected to further enhance the capabilities of stamping lines, making them smarter and more efficient.

AI and Machine Learning

Incorporating AI and machine learning into stamping lines can lead to predictive maintenance, reducing downtime and improving efficiency.

Internet of Things (IoT)

IoT can facilitate real-time monitoring and data analysis, enabling manufacturers to optimize production processes.

Conclusion

In conclusion, automatic metal stamping lines are a crucial component of modern manufacturing, offering numerous benefits in terms of efficiency, precision, and cost-effectiveness. As technology continues to evolve, these systems are expected to become even more sophisticated, opening up new possibilities for manufacturers worldwide.

FAQs

What is an automatic metal stamping line?

An automatic metal stamping line is a system that automates the process of shaping or cutting metal using a series of machines and tools.

How does automation improve metal stamping?

Automation improves metal stamping by increasing efficiency, precision, and reducing the likelihood of human error.

What industries use automatic metal stamping?

Industries such as automotive, electronics, and medical device manufacturing commonly use automatic metal stamping.

This article contains affiliate links. We may earn a commission at no extra cost to you.