In the world of construction and design, understanding the costs associated with architectural metal fabrication is crucial. Whether you’re an industrial manufacturer or a construction enthusiast, having a clear picture of these expenses can help you plan better and execute projects more efficiently. This Architectural Metal Fabrication Cost Guide aims to provide insights into the various aspects that influence costs and how to manage them effectively.

Understanding Architectural Metal Fabrication

Before diving into costs, it’s essential to grasp what architectural metal fabrication entails. This process involves crafting metal structures and components that are integral to building designs. From skyscrapers to intricate sculptures, metal fabrication plays a vital role. For a comprehensive introduction, consider visiting this external resource.

Types of Metals Used

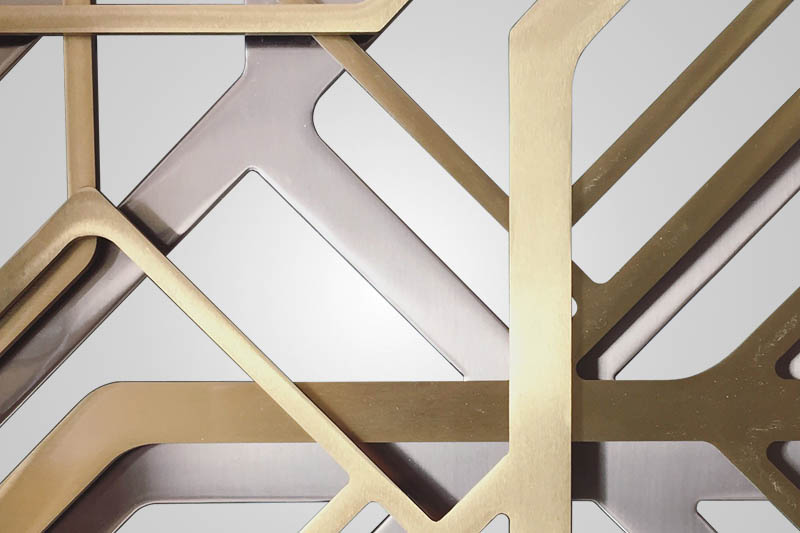

Different metals have varying properties, which affect their suitability for specific applications. Commonly used metals include steel, aluminum, copper, and brass. Each metal has unique characteristics that influence both its functionality and cost.

Importance of Design in Fabrication

The design phase is critical in architectural metal fabrication. It determines the complexity of the project, which directly impacts costs. Complex designs require more time, precision, and resources, leading to higher expenses. Explore more on how modern designs influence costs here.

Factors Influencing Fabrication Costs

Several factors contribute to the overall cost of metal fabrication. Understanding these can help you budget effectively and avoid unexpected expenses.

Material Costs

The cost of raw materials is a significant component of fabrication expenses. Prices fluctuate based on market demand, availability, and quality. It’s crucial to choose materials that meet both your budget and project requirements.

Labor Costs

Fabrication is labor-intensive, requiring skilled workers. Labor costs vary depending on the project’s complexity and the expertise required. Investing in experienced fabricators can ensure high-quality outcomes but may increase costs.

Equipment and Technology

Advanced machinery and technology can enhance efficiency and precision in fabrication. However, these come at a cost. Balancing the use of technology with budget constraints is vital. For more insights on how these factors affect costs, check out this guide.

Managing and Reducing Costs

Effective cost management is essential for staying within budget while ensuring quality. Here are some strategies to consider.

Efficient Material Use

Optimizing material use can significantly reduce waste and costs. Precise measurements and careful planning during the design phase can help achieve this.

Regular Maintenance

Maintaining metal finishes and structures can extend their lifespan and reduce long-term costs. Learn more about maintenance techniques here.

Future Trends in Metal Fabrication Costs

The metal fabrication industry is continuously evolving, with trends impacting costs. Staying informed about these changes can help you anticipate future expenses.

Innovations in Fabrication Techniques

New techniques and technologies are emerging, offering more efficient and cost-effective solutions. Keeping up with these innovations can provide a competitive edge.

Sustainability in Metal Fabrication

As sustainability becomes a priority, eco-friendly practices in metal fabrication are gaining traction. While these may initially increase costs, they offer long-term benefits and align with environmental goals.

Conclusion

Understanding the architectural metal fabrication cost guide is vital for successful project management. By considering the factors outlined above and embracing efficient practices, you can achieve cost-effective and high-quality outcomes. For further reading on architectural metals, visit this article.

FAQ

What metals are most cost-effective for fabrication?

Steel and aluminum are often considered cost-effective due to their durability and availability.

How can I reduce labor costs in metal fabrication?

Investing in efficient machinery and training workers can enhance productivity, reducing labor costs.

Are sustainable practices more expensive in fabrication?

Initially, they may be, but they offer long-term savings and environmental benefits.

This article contains affiliate links. We may earn a commission at no extra cost to you.