In the world of metalworking, aluminum stamping techniques play a crucial role in shaping the components used in various industries. From automotive to consumer electronics, these techniques form the backbone of numerous manufacturing processes. Understanding the intricacies of aluminum stamping can offer significant advantages in terms of cost, efficiency, and product quality.

The importance of aluminum stamping techniques cannot be overstated, especially for industrial manufacturers aiming to optimize their production lines. By leveraging advanced methods, businesses can enhance their capabilities, ensuring they meet the ever-growing demands of modern markets.

What is Aluminum Stamping?

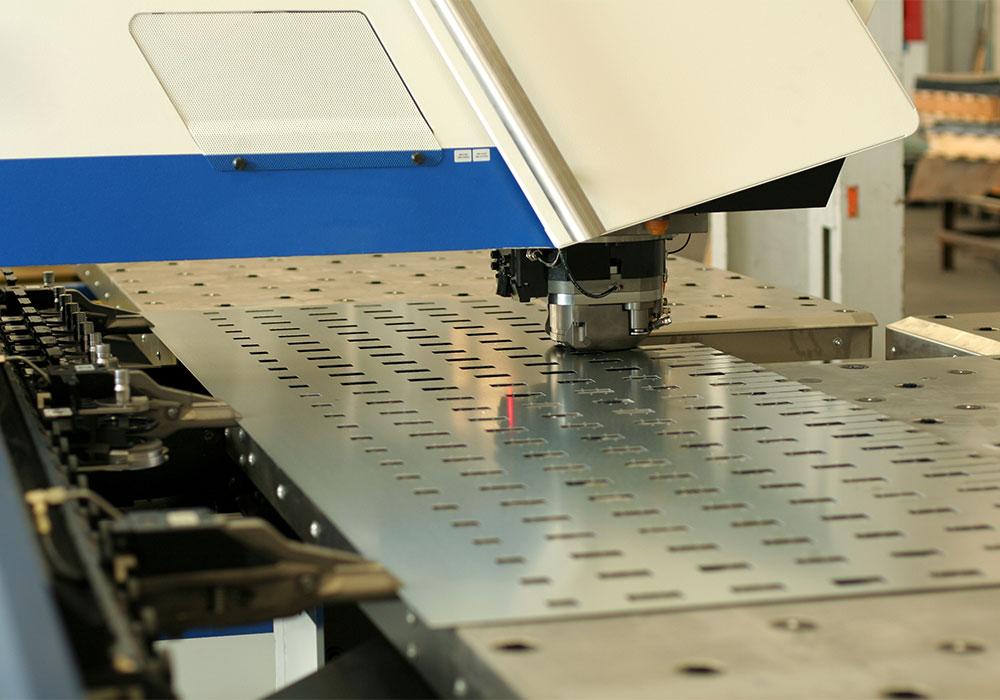

Aluminum stamping is a process used to convert flat aluminum sheets into specific shapes. It involves the use of a stamping press that either cuts or forms the metal. This technique is favored for its ability to produce high volumes of parts with consistent quality.

One of the key advantages of aluminum in this process is its lightweight nature combined with strength. This makes it ideal for applications where weight reduction is crucial, such as in the automotive and aerospace industries.

Key Techniques in Aluminum Stamping

1. Blanking

Blanking is the process of cutting the raw metal sheet into a predefined shape. This is often the first step in the stamping process, preparing the aluminum for further shaping and forming.

2. Bending

Bending involves deforming the aluminum along a straight line to achieve a desired angle or shape. It’s a critical step in creating components that require a specific contour.

3. Coining

Coining is a precision stamping technique used to create fine details on a metal surface. This method is especially useful for producing intricate designs and achieving tight tolerances.

Advantages of Aluminum Stamping

The use of aluminum stamping techniques offers several benefits:

- Efficiency: High-speed production with minimal waste.

- Cost-effectiveness: Reduces material usage and labor costs.

- Consistency: Ensures uniformity across produced parts.

- Versatility: Suitable for various industries, from automotive to electronics.

Challenges in Aluminum Stamping

Despite its advantages, aluminum stamping presents some challenges. The softness of aluminum can lead to issues like tearing and galling. Proper tool maintenance and lubrication are essential to mitigate these problems.

Innovations in Aluminum Stamping

Advancements in technology have led to innovative approaches in aluminum stamping techniques. For example, the integration of monitoring systems allows for real-time analysis of the stamping process, enhancing precision and reducing downtime.

Applications of Aluminum Stamping

The versatility of aluminum stamping makes it applicable in numerous fields:

- Automotive: Used for body panels, brackets, and other structural components.

- Aerospace: Essential in manufacturing lightweight yet strong parts.

- Consumer Electronics: Integral in producing cases and frames. Learn more about its role in consumer electronics.

Choosing the Right Aluminum Stamping Technique

Selecting the appropriate aluminum stamping technique depends on factors such as the complexity of the part, production volume, and budget constraints. Understanding these aspects helps manufacturers make informed decisions that align with their operational goals.

Future Trends in Aluminum Stamping

As industries evolve, so do the demands on manufacturing processes. The future of aluminum stamping lies in automation and smart technologies, which promise to deliver even greater efficiencies and capabilities.

Conclusion

For industrial manufacturers, mastering aluminum stamping techniques is not just about producing parts; it’s about crafting solutions that drive innovation and success. By embracing these methods, companies can position themselves at the forefront of their industries.

FAQs

What is the main advantage of using aluminum in stamping?

The main advantage is its lightweight nature combined with strength, making it ideal for industries like automotive and aerospace.

How does technology impact aluminum stamping?

Technology, such as monitoring systems, enhances precision and reduces downtime, leading to more efficient production processes.

What are common challenges in aluminum stamping?

The softness of aluminum can lead to issues such as tearing and galling, which require proper tool maintenance and lubrication to address.

For further details on metalworking processes, visit Rapid Direct or The Fabricator.

This article contains affiliate links. We may earn a commission at no extra cost to you.