The integration of AI in metal stamping equipment has ushered in a new era of efficiency and precision in the manufacturing industry. In a rapidly evolving technological landscape, industrial manufacturers are increasingly turning to artificial intelligence to enhance their operations. The advent of AI in metal stamping is not just a trend; it’s a transformative force reshaping the way we approach production processes.

Understanding Metal Stamping

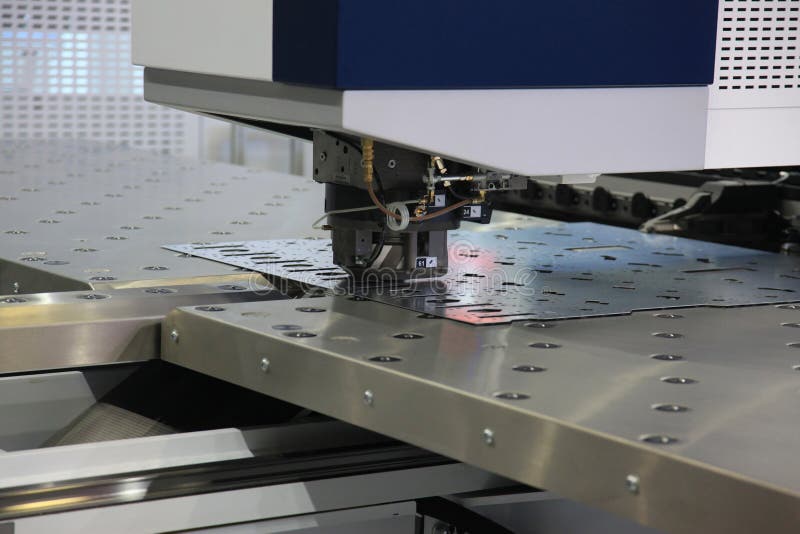

Metal stamping is a manufacturing process that involves shaping flat metal sheets into specific forms. This method is widely used in various industries, including automotive, electronics, and appliances. The process involves a series of steps, such as blanking, punching, bending, and piercing, to achieve the desired shape. Traditional stamping methods, however, have limitations in terms of precision and speed.

The Role of AI in Metal Stamping

Integrating AI into metal stamping equipment has addressed many of these limitations. AI-powered systems can analyze vast amounts of data to optimize stamping processes, ensuring precision and reducing waste. With AI, manufacturers can achieve higher accuracy in product dimensions and improve overall efficiency.

Benefits of AI in Metal Stamping

The benefits of incorporating AI in metal stamping are manifold. Here’s how AI is making a difference:

- Increased Precision: AI algorithms can predict and adjust for variations in material properties, ensuring consistent quality in the final product.

- Enhanced Efficiency: AI systems can streamline production processes, reducing downtime and increasing throughput.

- Cost Reduction: By minimizing waste and optimizing resource use, AI helps manufacturers reduce operational costs.

AI and Quality Control

AI plays a crucial role in quality control within metal stamping. By continuously monitoring the production process, AI systems can detect defects in real-time, allowing for immediate corrective actions. This capability not only improves product quality but also prevents costly recalls and rework.

Challenges in Implementing AI

While the advantages of AI in metal stamping are clear, implementing such systems is not without challenges. Manufacturers must invest in training their workforce to operate and maintain AI-enabled equipment. Additionally, the initial cost of integrating AI technology can be substantial.

Overcoming Implementation Challenges

To successfully implement AI in metal stamping, manufacturers should focus on:

- Providing comprehensive operator training to ensure employees are equipped with the necessary skills.

- Investing in reliable AI technologies that can seamlessly integrate with existing systems.

- Collaborating with technology providers to customize solutions tailored to specific manufacturing needs.

Future of AI in Metal Stamping

The future of AI in metal stamping looks promising. As technology continues to advance, we can expect even more sophisticated AI systems capable of handling complex tasks. These advancements will further enhance manufacturing efficiency, quality, and scalability.

Industry Adoption

Industries are gradually adopting AI-powered metal stamping equipment. Companies that have embraced this technology are already witnessing significant improvements in their production processes. As AI becomes more accessible and cost-effective, wider adoption is inevitable.

Real-World Applications

AI in metal stamping is applicable across various sectors. In the automotive industry, for instance, AI helps in producing components that meet stringent quality standards. Similarly, in consumer electronics, AI ensures precise and efficient fabrication of intricate parts.

Case Study: AI in Automotive Stamping

The automotive industry is a prime example of how AI is transforming metal stamping. By leveraging AI, manufacturers can produce complex components with high precision, meeting the increasing demand for lightweight and efficient vehicles.

Conclusion

In conclusion, the integration of AI in metal stamping equipment is revolutionizing the manufacturing landscape. By enhancing precision, efficiency, and quality control, AI is paving the way for a future where manufacturing processes are more streamlined and cost-effective. As the industry continues to evolve, embracing AI technology will be crucial for manufacturers aiming to stay competitive.

FAQs

What is metal stamping?

Metal stamping is a process that involves shaping flat metal sheets into specific forms using a die and press machine.

How does AI improve metal stamping?

AI improves metal stamping by enhancing precision, efficiency, and quality control through data analysis and process optimization.

What are the challenges of implementing AI in metal stamping?

Challenges include the initial cost of technology integration and the need for workforce training to operate AI-enabled equipment.

This article contains affiliate links. We may earn a commission at no extra cost to you.