The field of aerospace stamping technology is a crucial component in the modern manufacturing landscape. This technology has reshaped how components are created for aircraft, offering precision, efficiency, and innovation. As the industry progresses, understanding the intricacies of this technology becomes essential for industrial manufacturers.

Introduction to Aerospace Stamping

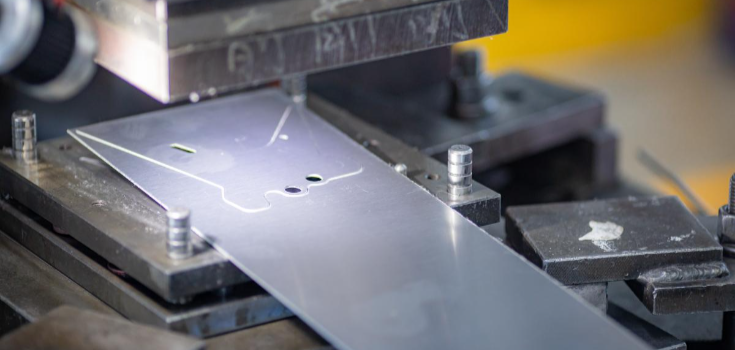

Aerospace stamping technology involves the process of transforming metal sheets into precise components used in aircraft manufacturing. This method ensures high-quality and durable parts, essential for the safety and performance of aircraft.

Historical Development of Stamping in Aerospace

The evolution of metal stamping in aerospace has been significant. Initially, simpler methods were employed, but as technology advanced, so did the techniques, leading to more sophisticated and precise manufacturing processes.

The Role of Precision in Aerospace Stamping

Precision is paramount in aerospace stamping technology. Aircraft components must meet exact specifications to ensure safety and functionality. This technology allows for the production of parts with minimal error, enhancing overall aircraft performance.

Advancements in Technology

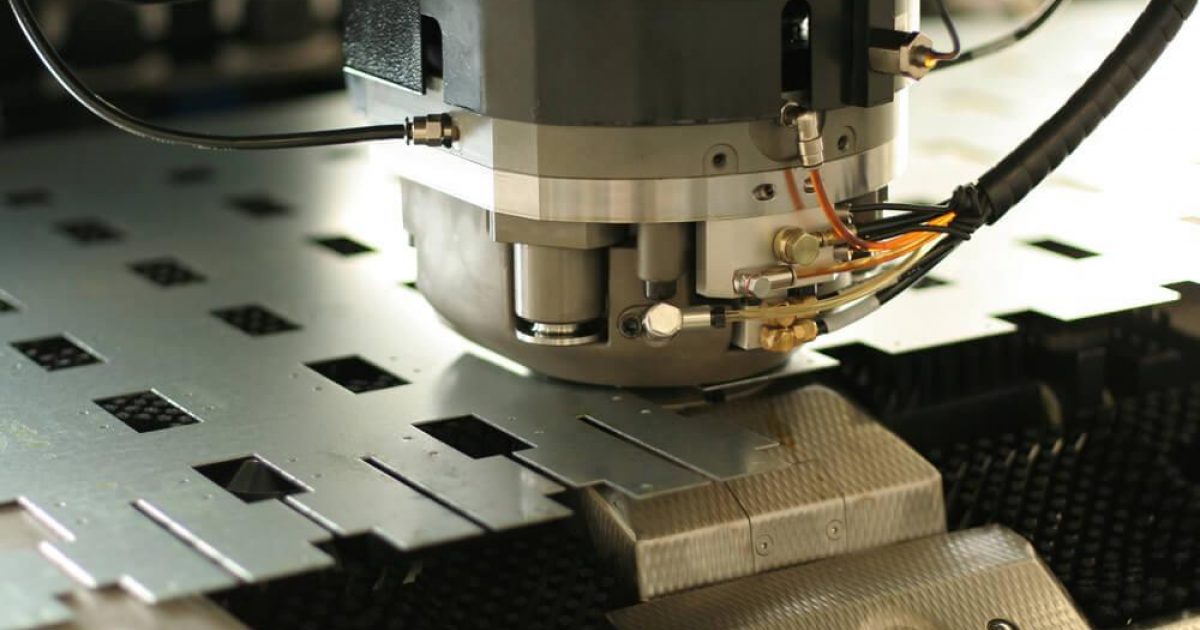

With the advent of computer-aided design (CAD) and computer-aided manufacturing (CAM), the precision in stamping has improved significantly. These technologies allow for meticulous planning and execution of stamping processes.

Materials Used in Aerospace Stamping

The choice of materials in aerospace stamping technology is critical. Common materials include aluminum, titanium, and high-strength alloys. Each material offers unique properties that contribute to the efficiency and safety of the final product.

Challenges Faced in Aerospace Stamping

Despite its advantages, aerospace stamping technology faces challenges such as material wastage, tool wear, and the need for high precision. Addressing these issues requires constant innovation and improvement in technology.

Solutions and Innovations

Developments in tool design and material science have provided solutions to these challenges. Innovations aim at reducing waste and enhancing tool durability, thus improving the overall efficiency of the stamping process.

Impact on Manufacturing Efficiency

The introduction of aerospace stamping technology has significantly improved manufacturing efficiency. It allows for faster production cycles while maintaining quality and consistency, crucial for meeting the demands of the aerospace industry.

Case Studies

Several aerospace companies have reported increased efficiency and reduced costs after implementing advanced stamping technologies. These case studies highlight the transformative impact of stamping technology on manufacturing.

The Future of Aerospace Stamping

Looking ahead, aerospace stamping technology is expected to evolve further. With ongoing research and development, future advancements could lead to even more efficient and sustainable manufacturing processes.

Environmental Considerations

Sustainability is becoming increasingly important in manufacturing. Efforts are being made to develop eco-friendly stamping processes that minimize environmental impact while maintaining efficiency and quality.

The Role of Training and Expertise

Proper training and expertise are vital in ensuring the success of aerospace stamping technology. Skilled operators and engineers are needed to handle advanced machinery and ensure precise component production.

Training Programs

Many institutions offer specialized training programs to equip individuals with the necessary skills for successful careers in aerospace stamping. These programs focus on both theoretical knowledge and practical application.

Quality Control Measures

Quality control is a critical aspect of aerospace stamping technology. Rigorous testing and inspection processes are in place to ensure that all components meet the highest standards before being used in aircraft assembly.

Inspection Techniques

Advanced inspection techniques, such as non-destructive testing and 3D scanning, play a significant role in maintaining quality standards in aerospace stamping.

Conclusion

Aerospace stamping technology is an integral part of modern manufacturing, offering numerous benefits including precision, efficiency, and innovation. As the industry continues to evolve, staying informed about the latest developments and maintaining high standards of training and quality control will be essential for success.

For more information, visit the Wikipedia page on stamping.

FAQ

What is aerospace stamping technology?

Aerospace stamping technology involves using machinery to shape metal sheets into precise components for aircraft manufacturing.

Why is precision important in aerospace stamping?

Precision ensures that components meet exact specifications, which is crucial for aircraft safety and performance.

What materials are commonly used in aerospace stamping?

Common materials include aluminum, titanium, and high-strength alloys, each offering unique properties for aerospace applications.

This article contains affiliate links. We may earn a commission at no extra cost to you.