In today’s fast-paced world, where precision and efficiency are of utmost importance, choosing the right technology for metal cutting is crucial. In our exploration of the advantages of laser over plasma, we delve into why many industrial manufacturers are making the shift towards laser technology. The primary advantages of laser over plasma can greatly impact productivity, cost-effectiveness, and quality of output.

The Basics of Metal Cutting Technologies

Understanding Laser Cutting

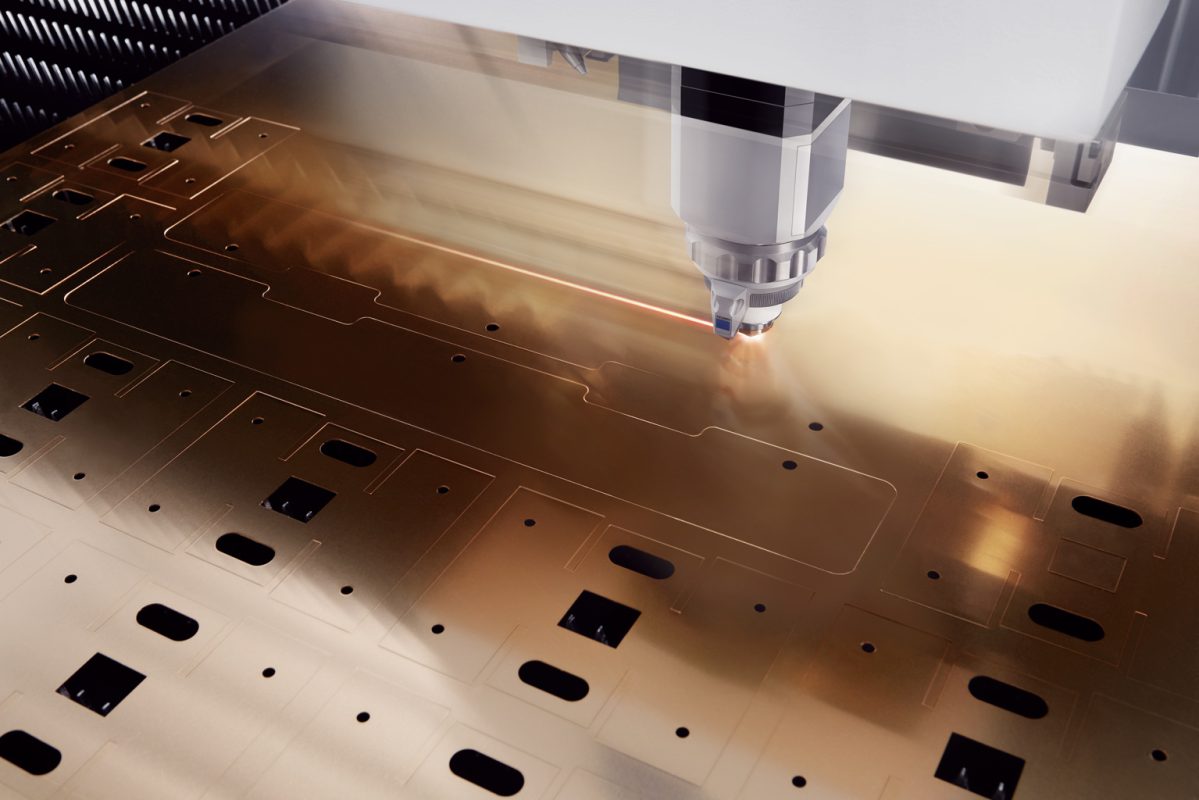

Laser cutting involves using a high-powered laser beam to slice through materials. The laser technology uses a focused light source to achieve high precision and intricacy in cutting.

Comprehending Plasma Cutting

Plasma cutting, on the other hand, utilizes a jet of hot plasma to cut through metal. It is favorable for its speed, especially in thick materials, but may lack precision compared to lasers.

Highlighting the Advantages of Laser Over Plasma

Precision and Accuracy

One of the major advantages of laser over plasma is precision. Lasers offer higher accuracy ideal for intricate designs and small-scale metal pieces where details matter.

Quality of Finish

Laser cutting reduces burrs, resulting in a smoother finish. Addressing how to achieve clean cuts in metals, clean metal cutting principles are naturally advantageous in laser technology.

Material Versatility

Laser cuts efficiently handle a range of materials like aluminum and stainless steel, enhancing versatility. For thin metals and those requiring precise cuts, lasers excel.

Economic Efficiency

Operational Costs

Laser technology often leads to lower operational costs in comparison to plasma cutters due to reduced material waste and energy efficiency over time.

Speed and Productivity

When it comes to speed, lasers provide rapid results, especially in fine cutting requirements. This efficiency boost afterward enhances overall production timelines.

Environmental and Safety Considerations

Energy Conservation

Lasers consume less power, which can provide a more environmentally friendly option than plasma cutters.

Improved Safety

With fewer physical hazards and more controlled cutting processes, lasers tend to offer enhanced safety measures within the manufacturing plant.

Technological Innovations and Adaptations

Software Integrations

Laser technology frequently incorporates advanced software for precise control, integrating CAD/CAM systems for optimized operational outcomes.

Future Prospects in Industrial Manufacturing

With continuous advancements, lasers promise future possibilities, such as enhanced automation in fabrication procedures. Metal fabrication innovations are expanding rapidly on this front.

Application Scenarios Across Industries

Aerospace and Automotive

Laser precision is essential in sectors like aerospace and automotive, where detail-intensive components are standard. This application can significantly reduce production errors.

Electronics and Electricals

Precision requirements in electronics manufacture make laser the preferred method for consistency and minimalistic discrepancies.

Architecture and Design

Lasers allow for unique architectural designs and customized solutions in decorative metal piecesareas where plasma may fall short. For further insights, explore the impact of laser technology in architecture with this external resource at Precision Metal Cutting.

The Industrial Edge

Read more on achieving minimal burrs and processing clean and precise cuts in metal works, favoring laser technology across industries.

Advantages of Laser Over Plasma in Summary

The comparative benefits of using laser technology over plasma highlight not only enhanced precision and efficiency but also reduced costs, improved safety, and environmental considerations. As laser technology continues to evolve, it increasingly becomes a critical component for numerous industrial applications.

FAQs

What are the maintenance costs associated with laser cutting?

Maintenance for laser systems can be lower in the long run compared to plasma due to fewer mechanical parts and lower wear and tear.

How does laser cutting affect material waste?

Due to its precision, laser cutting significantly reduces material waste, offering a more sustainable option than conventional methods.

Is laser cutting suitable for all types of metals?

While highly versatile, laser cutting is best suited for metals like stainless steel, aluminum, and thin sheets, offering precision inherently.

This article contains affiliate links. We may earn a commission at no extra cost to you.